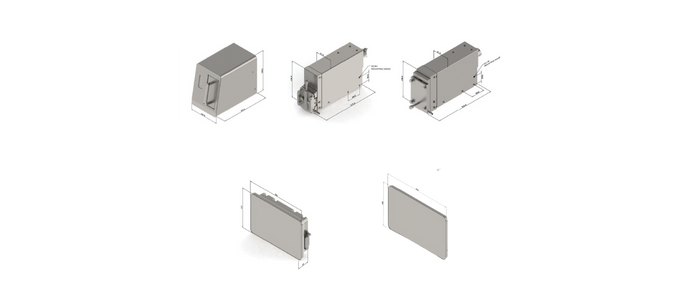

Domino Cx150i Large Character Inkjet Printer

Superior High-Resolution Printing on Non-Porous Materials

Domino Cx150i is a high-performance inkjet printing system developed to produce sharp, reliable and repeatable print results on non-porous substrates, enhancing both product presentation and brand visibility directly on the packaging surface.

With a comprehensive set of connectivity interfaces, the printer integrates seamlessly into existing manufacturing environments and is fully Industry 4.0 compliant, enabling straightforward integration with ERP and MES platforms as well as leading coding automation solutions.

The intuitive QuickStep touchscreen interface simplifies daily operation: parameters can be modified in seconds and new print designs created effortlessly, helping to reduce changeover times and improve operator efficiency.

Designed for maximum uptime and low maintenance requirements, the system allows ink replenishment without stopping production, operates without compressed air and, thanks to UV inks cured by LED lamps, delivers energy-efficient and environmentally responsible coding performance.

Why Choose the Domino Cx150i Large Character Inkjet Printer

![]()

Delivers high-definition printing up to 600 dpi horizontally, ensuring precise, uniform codes even across wide print areas.

![]()

Achieves production speeds of up to 200 m/min at 100 dpi, with performance scalable according to the selected print resolution.

![]()

The Domino Cx150i operates with high-contrast UV inks supplied in 500 ml low-waste flexible pouches, combined with efficient UV LED curing for reduced environmental impact.

Technical Information

Ink Base

| Ink base | Cx1-Inkbase A |

| Description | Cx150i ink supply unit designed for UV ink operation |

| Dimensions | Width 167.0 mm / Depth 276.1 mm / Height 230.5 mm / Weight 7.3 kg (excluding fasteners, power switch, latch, connector cover and mounting bracket) |

| Internal ink reservoir | 50 ml |

| Power input | 100–240 Vac, 50–60 Hz, 2 A |

| Power connection | 6 mm DC connector supplied via external power unit (included) |

| External interfaces | 1 × 24 Vdc input, 1 × encoder input, 3 × I/O ports, 2 × USB (Type A), 2 × RJ-45, 2 × IX |

Printhead

| Cx1-PH 32 A | Cx1-PH 65 A | |

|---|---|---|

| Description | 32.5 mm UV ink printhead for Cx150i | 65.0 mm UV ink printhead for Cx150i |

| Conduit length options | 1.5 m or 3.0 m | 1.5 m or 3.0 m |

| Dimensions | Width 61.0 mm / Depth 212.6 mm / Height 136.4 mm / Weight 1.92 kg | Width 61.0 mm / Depth 223.8 mm / Height 136.4 mm / Weight 2.05 kg |

| Maximum print height | 32.5 mm | 65.0 mm |

| Vertical resolution | 300 dpi | 150 dpi |

| Horizontal resolution | up to 600 dpi | up to 600 dpi |

| Nozzle-to-substrate distance | 23.3 mm | 32.7 mm |

TouchPanel

| User interface | 7” or 10” touchscreen with QuickStep operating software |

| Dimensions | 7” Width 182 mm / Depth 37 mm / Height 121 mm / Weight 0.8 kg 10” Width 256 mm / Depth 37 mm / Height 166 mm / Weight 1.2 kg |

System Specifications

| Operating temperature | 5–40 °C |

| Operating humidity | 10–90 % RH (non-condensing, max. 10 °C increase per hour) |

| Finish | Brushed stainless steel |

| Ingress protection | IP4X |

| Communication | Ethernet / Dynamark protocol, EDC (serial, TCP, USB), Domino Cloud Interface (DCI), Domino Coding Automation |

| Print speed | Up to 200 m/min @100 dpi, 100 m/min @200 dpi, 70 m/min @300 dpi, 47 m/min @450 dpi, 35 m/min @600 dpi |

| Inks* | High-contrast UV inks supplied in low-waste 500 ml flexible pouches |

| Recommended UV lamp specifications | 395 nm UV lamp with 8–12 W/cm² intensity over 20 mm travel at a 5 mm distance, ensuring effective curing up to 70 m/min linear speed.** |

* This system incorporates a quality management architecture that enables operation exclusively with Domino electronic components, using dynamic security features to prevent the use of non-Domino parts. Domino periodically issues electronic component updates to maintain system integrity.

** UV curing performance is application-dependent and influenced by multiple factors; validation testing is therefore always recommended.